Insert Spot Drills

NC Spot Drills

Nine9

Product Features

High-speed machining and long life helpful for cost reduction.

Usable in conjunction with machining centers, CNC lathes, CNC combined lathes, etc.

Inserts of specially designed shapes enable chatter-free, high-speed machining over a long life. In addition, economical four-edge inserts are also available (*two-edge inserts for some sizes).

Optional inserts are also available for round chamfering. (*NOT applicable to some tool holders.)

Inserts are made of carbide or cermet. Carbide inserts are available coated with TIN, TiALN, or DLC.

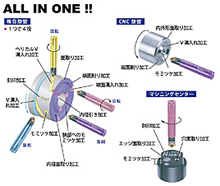

A single insert enables use for multiple purposes including centering, chamfering, V-grooving and engraving.

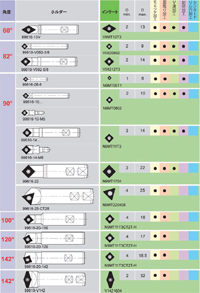

A broad selection of series is available with angles of 60°, 82°, 90°, 100°, 120° and 142°.

| Supported machines | Machining centers, CNC lathes, combined lathes, milling machines, etc. (*NOT usable with drill presses) |

|---|---|

| Applications | Centering, chamfering (chamfer, 30°, etc), engraving, V-grooving, facing, center drilling, turning, etc. |

Features of Nine9 NC Spot Drills

- Inserts specially designed for a long life!

- Each insert has four cutting edges. (*Two-edge inserts for some sizes)

- A single insert enables use for multiple purposes including centering, chamfering, V-grooving and engraving.

- Originally designed coated inserts enable high-speed machining!

- A broad selection is available with angles of 60°, 82°, 90°, 100°, 120° and 142°.

- Inserts are available coated with TiN, TiAlN, or DLC.

- The insert material is selectable from carbide and cermet.

- Optional inserts are also available for round chamfering. (*Not applicable to some tool holders.)

Product line-up

Features of Nine9 NC Spot Drills

Click here to download the brochure of attractively priced "NC Spot Drill Starter Sets."

- NC Spot Drill 60°

- NC Spot Drill 82°

- NC Spot Drill 90° (machining dia: 1 to 6 mm)

- NC Spot Drill 90° (machining dia: 2 to 10 mm)

- NC Spot Drill 90° (machining dia: 3 to 14 mm)

- NC Spot Drill 90° (machining dia: 3 to 22 mm)

- NC Spot Drill 90° (machining dia: 4 to 25 mm)

- NC Spot Drill 100°

- NC Spot Drill 120°

- NC Spot Drill 142°

- Extension bar (option)

Nine9 NC Spot Drill technical data (drilling conditions tables)

Click and check other Nine9 products.

About Nine9

Nine9 is a Taiwanese cutting tool manufacturer. The Nine9 brand is growing rapidly in applications including centering, chamfering and engraving. It offers innovatively designed indexable tools featuring high-efficiency cutting performance and high-durability in more than 40 countries around the world.

Usable in conjunction with machining centers, CNC lathes, combined lathes, milling machines, etc. Supported applications are extensive and include centering, internal chamfering, engraving, V-grooving, facing, center drilling, turning and grooving.

Many inserts of different designs, materials and coatings are available. A single tool holder enables various types of machining, helping to save costs with a low initial investment and high efficiency!