Multi-Point Compensating X-Ray Drilling Machine with Automatic Spindle Selection MMX-888ZT

For printed circuit boards

-

Operation example of two different size drilling

-

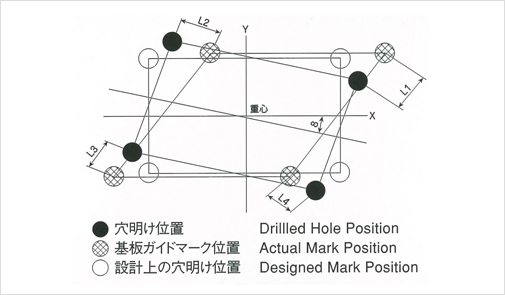

Example of four points compensating

-

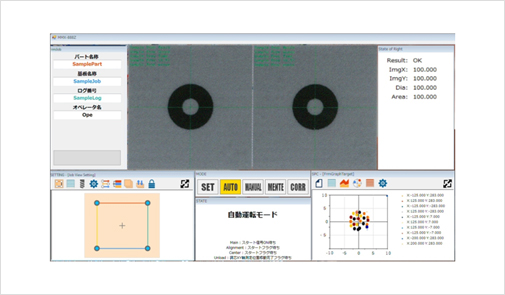

- Production Control

- Various Data that is necessary for production control such as distance between marks, distance between drilled holes, compensated amount, processing time, Good/NG, can be displayed on the monitor.

All of the data is very useful as a feedback for pre and post production control.

-

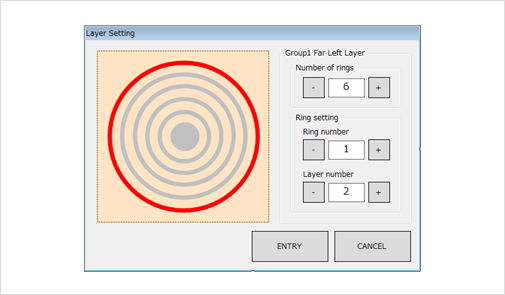

- Programming for Layer Analysis

- Misalignment of each layer can be measured with easy operation.

| Product name | Multi-Point Compensating X-Ray Drilling Machine with Automatic Spindle Selection |

|---|---|

| Product number | MMX-888ZT |

Functions and features

Analyzed data of compensating X-ray drilling machine which produced it for many years, renewed software and structure.

MMX-888ZT(multipoint distribution spindle selection type X-ray hole-cutters)is the most suitable for cutting reference holes for laser hole-cutters and exposure devices for substrate of build-up board having two different diameters.

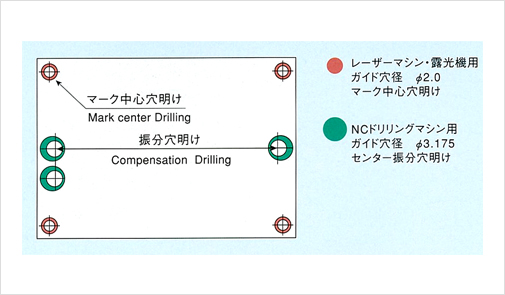

- Simultaneous drilling of holes of two different diameters

- Equipped with four switchable spindles for high-speed, high-accuracy simultaneous drilling of holes of two different diameters through a board (e.g., simultaneous drilling of NC and exposure guide holes)

- High-speed drilling

- Processing speed significantly improved via a new concept.

- Drilling with fewer burrs.

- Equipped with several new mechanisms for reducing burrs around holes drilled through low machinability materials (halogen-free materials, etc.) and hence most suitable for drilling guide holes for exposure machines or laser drilling machines.